The Beech Forests of the Appi Plateau that Supported Wood Working

There are extensive secondary forests of beech trees that surround the Appi Plateau. A secondary forest is a forest that was originally in the area that has regenerated naturally after the soil had been exposed due to natural disasters, such as typhoons or volcanic eruptions, or logging.

In the upper reaches of the Appi River, wood working, the base of lacquerware, was once very popular. At the foot of the mountains, there were villages of wood workers who cut trees from the broadleaf forest zone and carved them with a lathe. When cutting down the trees, the wood workers left a few mother trees per hectare and large trees that cannot be cut down with a saw. The leftover trees became the parent trees, and the seeds fell and germinated to regenerate as secondary forests. In the early Showa period around 1920, cattle and horses were actively grazing in the forests, foraging for bamboo and other vegetation that hindered the growth of young beech trees. This is said to be one of the reasons why the secondary forests around the Appi Plateau regenerated. This beautiful forest has been selected as one of the 100 best forests in Japan for a pleasant and relaxing walk.

Please start by taking a deep breath.

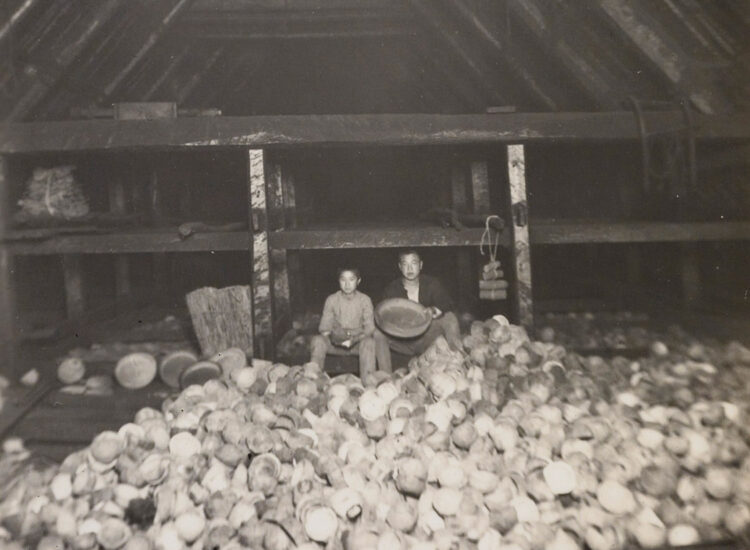

In the past, it was difficult to transport wood. For this reason, there were two main methods used by wood workers. The first method was to use the river: logs were cut and transported to the river basin by horse-drawn sledges during the winter, then floated into the swollen river as the snow melted in spring. The logs were then lifted out of the river when the water flow was calm. These logs were called haruki (spring wood), and the place where the logs were lifted from the river was called harukiba (the place of spring wood). At the harukiba, the logs were cut into the appropriate size and brought to the workshop where they were finished with a lathe. The other method was to move all the tools, including the lathe, to the site where the logs were cut down, and complete the majority of the work on the spot. It is believed that this method was rather mainstream in the days when there was no electric power because the lathe was turned by human power and saved labor compared to the energy required to transport the logs.

Photo provided by Hachimantai City, Institute for the Study of Japanese Folk Culture Kanagawa University

→Access to the Beech Forests of the Appi Plateau